How the F1T3® labelling system was conceived and developed

How was the F1T3® labelling system devised?

The best way to know is to talk to Loris Genasi, its inventor.

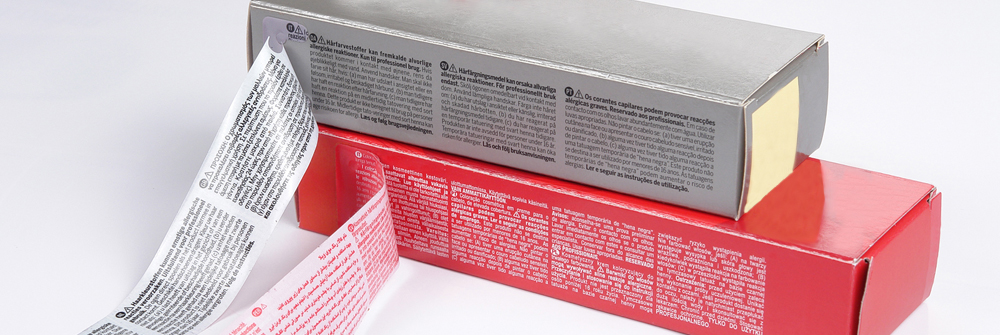

The F1T3® solution was offered for the first time to Colomer Italy S.p.A a company that manufactures professional dyes for hair and cosmetic products. It was given the Packology Award 2013 n the cosmetics packing category at the Packology trade fair held in Rimini. The prize was awarded to Colomer Italy S.p.A, to Eticpress S.r.l as the manufacturing company, and to Loris Genasi as the inventor and technical engineer of the F1T3® system.

Which was the panorama at Colomer Italy S.p.A before the F1T3® system was introduced?

It was back in 2009 when the cosmetics industry started to hear about the new European regulations to arrive. Under the new regulations, all hair dye manufacturers were to print the warnings outside the packages in all the languages of the countries where their products were marketed. There was growing concern. And Colomer Italy S.p.A. was one of the first companies to start working towards finding a solution to this problem- How can manufacturers comply with the regulation and print warnings on the small packs of their dyes?

How was this problem solved using the F1T3® labelling system?

The Packaging R&D department of Colomer Italy S.p.A asked me for a solution to create and print a label onto a tube or pre-formed box. At the beginning we thought about a multipage label. But the solution proved to be too costly for the company.

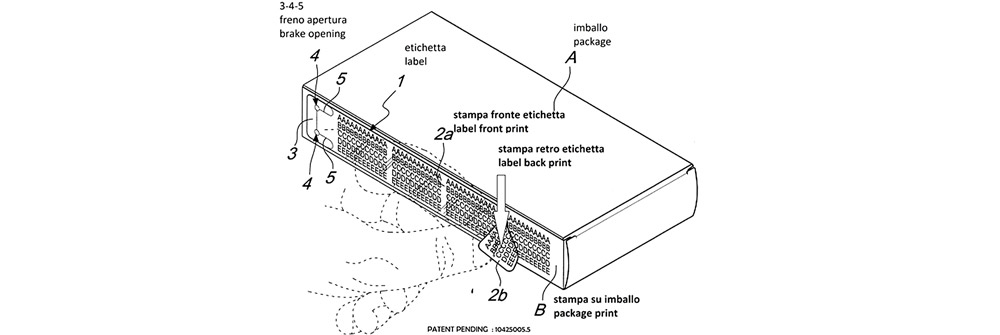

Then we found another alternative, designing and building a self-adhesive label printed on both front and back (adhesive side). The glue did the trick. We treated the adhesive so that the label printed on both sides can be applied on the text beneath and raised again without damaging the package. So the text can be distributed on 3 sides- label front, label back and on the package itself.

And that was how the F1T3® – From 1 to 3- system was born.

Which were the advantages for the company?

Thanks to the F1T3® system, Colomer Italy S.p.A. was able to:

• halve costs compared with a traditional multipage label

• triple the space that can be used on the pack

• preserve the product appearance

• keep packaging speed the same at their automatic lines

• ensure information remain readable along time, since raising the label does not affect the text beneath

Has the F1T3® system been upgraded?

Once we were able to print both label and pack using the F1T3® system, we wanted this process to be made automatically. The technology partner we chose to design and build these automatic labelling machines was Euroetik S.r.l, represented by Mr. Gianluca Zapparoli, Sales Manager and Design Office Manager. Three years later and a continuous and daily output, the labelling machinery proved to be reliable and efficient.